Description

Servohydraulic Dynamic Torsion Test Systems easily meet the difficult demands of both static and dynamic torsion testing requirements with a precision-aligned, high-rigidity double-column body. It has a sliding system that can be adjusted according to the sample shape and size. Depending on the test application, vertically or horizontally positioned bodies can be used.

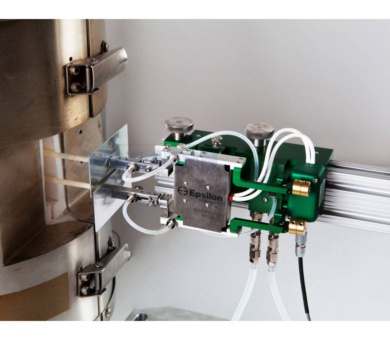

EDC series DOLI digital controllers and specially developed torque sensors for dynamic testing (fatigue rated torque sensor) enable to offer fully integrated solutions to meet the most demanding applications.

DOLI Test&Motion dynamic test software provides full system control over a computer, thanks to its features such as performing dynamic fatigue tests in different waveforms, calibration, limit setting, displaying and recording instant sensor data, and reporting.

The software automatically recognizes the connected sensors and the calibration values are kept on the plates on the sensor. Thus, the calibration values are not lost.

servo hydraulic dynamic torsion test machines are suitable for high frequency and high cycle torsional fatigue testing. It performs dynamic torsion tests by means of a servo hydraulic rotary actuator. Sensitive servo valves are used in the system. It can be produced in capacities up to 50,000 Nm torque capacity thanks to its servo hydraulic drive.

It can be produced in different capacity and frequency ranges according to user needs and test requirements.

dynamic torsion testing machines are generally used to determine the fatigue life of axles, timing belts, wheels, wheel coupling shafts and shafts.

Contact us now to get more detailed information about Servohydraulic Torsion Fatigue Testing Machines or to request a quote.

Reviews

There are no reviews yet.